Your Trusted Gaskets Supplier in Malaysia

With over a decade of expertise, Mumtaz Energy is a leading supplier of top-quality gaskets. Our dedication to quality has earned us the trust of clients throughout the region. As a top supplier in Malaysia, we offer a comprehensive range of gaskets, including Nonmetallic Flat Cut Gaskets, Spiral Wound Gaskets, Ring Type Joint (RTJ) Gaskets, and Flange Insulation Gaskets.

At Mumtaz Energy, we take pride in providing gaskets that meet the highest standards and are meticulously tailored to the specific requirements of oil and gas facilities.

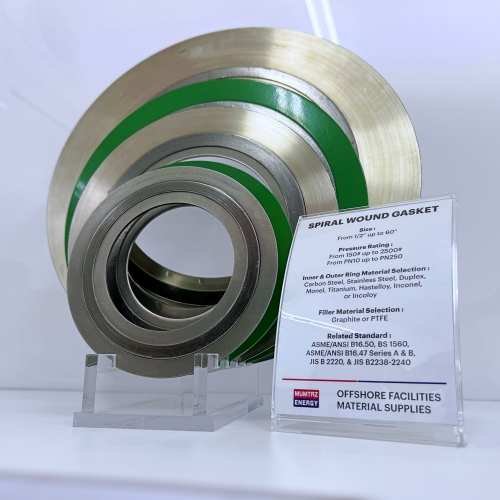

Spiral Wound Gaskets

As a trusted supplier of Spiral Wound Gaskets in Malaysia, Mumtaz Energy is committed to delivering products that comply with the following international standards:

- ASME B16.20 – Metallic Gaskets for Pipe Flanges

- API 601 – Metallic Gaskets for Refinery Piping

- EN 1514-2 – Flanges and Their Joints – Gaskets for Class-Designated Flanges

- ISO 7483 – Dimensions of Spiral Wound Gaskets for Use with Flanges

- BS 3381 – Specification for Spiral Wound Gaskets for Use with Flanges

- MSS SP-44 – Steel Pipeline Flanges

- DIN 2690 – Gaskets for Flanges – Spiral Wound Gaskets

- NACE MR0175/ISO 15156 – Petroleum and Natural Gas Industries

Ring Type Joint Gaskets

As a top supplier of Ring Type Joint (RTJ) Gaskets in Malaysia, Mumtaz Energy is dedicated to delivering products that meet the following international standards:

- ASME B16.20 – Metallic Gaskets for Pipe Flanges—Ring-Joint, Spiral-Wound, and Jacketed

- API 6A – Specification for Wellhead and Christmas Tree Equipment

- API 6B – Specification for Flanged Wellhead and Christmas Tree Equipment

- API 6BX – Specification for BX-Type Flanges

- ASME B16.5 – Pipe Flanges and Flanged Fittings

- ASME B16.47 Series A and B – Large Diameter Steel Flanges (NPS 26 through NPS 60)

Ring Type Joint Gaskets

As a top supplier of Ring Type Joint (RTJ) Gaskets in Malaysia, Mumtaz Energy is dedicated to delivering products that meet the following international standards:

- ASME B16.20 – Metallic Gaskets for Pipe Flanges—Ring-Joint, Spiral-Wound, and Jacketed

- API 6A – Specification for Wellhead and Christmas Tree Equipment

- API 6B – Specification for Flanged Wellhead and Christmas Tree Equipment

- API 6BX – Specification for BX-Type Flanges

- ASME B16.5 – Pipe Flanges and Flanged Fittings

- ASME B16.47 Series A and B – Large Diameter Steel Flanges (NPS 26 through NPS 60)

Flange Insulation Gaskets

As a trusted supplier of Flange Insulation Gaskets in Malaysia, Mumtaz Energy is committed to delivering products that comply with the following international standards:

- ANSI/ASME B16.5 – Pipe Flanges and Flanged Fittings

- ASTM F568M – Standard Specification for Carbon and Alloy Steel Externally Threaded Metric Fasteners

- NACE SP0108-2008 – Standard Practice: Pipeline Coatings for External Corrosion Control

- MSS SP-58 – Pipe Hangers and Supports

- API 6FB – Specification for Fire Test for End Connections

- ASME B16.47 Series A and B – Large Diameter Steel Flanges (NPS 26 through NPS 60)

Nonmetallic – Flat Cut Gaskets

As a top supplier of Nonmetallic-Flat Cut Gaskets in Malaysia, Mumtaz Energy is committed to delivering products that comply with the following international standards:

- BS 7531 – Specification for Non-Metallic Flat Gaskets

- ASME B16.21 – Nonmetallic Flat Gaskets for Pipe Flanges

- ASTM F104 – Standard Classification System for Nonmetallic Gasket Materials

- ASTM D1418 – Standard Practice for Rubber and Rubber Latices—Nomenclature

- ASTM D2000 – Standard Classification System for Rubber Products in Automotive Applications

- ASTM F36 – Standard Test Method for Compressibility and Recovery of Gasket Materials

- ASTM F37 – Standard Test Methods for Seal ability of Gasket Materials

- EN 1514-1 – Flanges and their joints – Dimensions of gaskets for PN-designated flanges

- DIN 2690 – Gaskets for Flanges

Nonmetallic – Flat Cut Gaskets

As a top supplier of Nonmetallic-Flat Cut Gaskets in Malaysia, Mumtaz Energy is committed to delivering products that comply with the following international standards:

- BS 7531 – Specification for Non-Metallic Flat Gaskets

- ASME B16.21 – Nonmetallic Flat Gaskets for Pipe Flanges

- ASTM F104 – Standard Classification System for Nonmetallic Gasket Materials

- ASTM D1418 – Standard Practice for Rubber and Rubber Latices—Nomenclature

- ASTM D2000 – Standard Classification System for Rubber Products in Automotive Applications

- ASTM F36 – Standard Test Method for Compressibility and Recovery of Gasket Materials

- ASTM F37 – Standard Test Methods for Seal ability of Gasket Materials

- EN 1514-1 – Flanges and their joints – Dimensions of gaskets for PN-designated flanges

- DIN 2690 – Gaskets for Flanges

Understanding Gaskets for Piping Systems in the Oil and Gas Industry

Spiral Wound Gaskets are versatile and highly effective sealing solutions engineered to meet the demanding conditions of various industrial applications. Manufactured through a precise process that involves alternating layers of metal strips and non-metallic fillers, these gaskets offer exceptional mechanical resistance, resilience, and sealing capabilities. They are ideal for use in flange joints, boilers, heat exchangers, pressure vessels, and valves across industries such as oil, gas, and petrochemical.

Spiral Wound Gasket Style R or Style S (Filler Only)

Style R is the foundational design in our range of Spiral Wound Gaskets. Featuring metal strips with minimal filler material around the inner and outer diameters, this style is specifically designed to maintain compression and sealing integrity in tongue and groove or male and female flange joints. Its robust construction makes it suitable for a wide range of temperatures and pressures.

Applications of Style R:

- Tongue and groove flanges

- Male and female flange joints

- Applications requiring a basic yet effective sealing solution

Spiral Wound Gasket Style RIR (Filler and Inner Ring)

Style RIR Spiral Wound Gaskets incorporate an inner ring designed to prevent the accumulation of solids and reduce turbulent flow. This design also minimizes erosion at the flange faces, ensuring prolonged service life. The inner ring adds an extra layer of protection, making this style ideal for use in male and female flanges where precise sealing is critical.

Applications of Style RIR:

- Male and female flanges

- Systems with high flow velocities

- Applications prone to erosion or solid buildup

Spiral Wound Gasket Style CG (Outer Ring and Filler)

Style CG features a centering ring that ensures accurate alignment on the flange face, providing additional radial strength to the spiral ring. This design enhances stability and protection, making it suitable for flat face and raised face flanges. The centering ring helps distribute the load evenly across the gasket, improving its sealing performance under varying pressure conditions.

Applications of Style CG:

- Flat face flanges

- Raised face flanges

- Applications requiring enhanced gasket stability

Spiral Wound Gasket Style CGI (Outer Ring, Filler, and Inner Ring)

Style CGI combines the benefits of both the centering ring and the inner ring, offering superior sealing performance in extreme conditions. This style is engineered for applications that involve high temperature, high pressure, or corrosive media. The additional inner ring provides reinforcement, making Style CGI ideal for critical environments above Class 900 or in situations where sealing reliability is paramount.

Applications of Style CGI:

- High-temperature and high-pressure environments

- Corrosive media

- Critical applications where sealing reliability is essential

As a trusted supplier of Spiral Wound Gaskets in Malaysia, Mumtaz Energy provides high-quality gaskets that adhere to international standards, ensuring both safety and optimal performance for your projects. Contact us today to find the perfect gasket solution for your needs.

Ring Type Joint (RTJ) Gaskets are essential components for high-pressure and high-temperature applications in the oil and gas industry. These metal gaskets are specifically designed to create a reliable seal in flange assemblies, ensuring leak-proof connections in critical operations such as offshore drilling, petrochemical processing, and pressure vessel construction.

RTJ Gaskets Style R Oval

The Style R Oval RTJ gasket is engineered for a precise fit within the flange groove, offering a metal-to-metal seal that can withstand high-pressure environments. This gasket is commonly used in applications where an original, traditional design is required, providing dependable sealing performance in demanding conditions.

RTJ Gaskets Style R Octagonal

The Style R Octagonal RTJ gasket features an innovative eight-sided design that enhances sealing efficiency. With its superior performance in both high-pressure and high-temperature environments, this gasket is the preferred choice for modern applications requiring robust sealing solutions.

RTJ Gaskets Style RX

Designed for even greater pressure resistance, the Style RX RTJ gasket provides an advanced sealing solution for environments with pressures up to 5,000 psi. Its unique profile is particularly effective in applications subject to vibration and dynamic loads, ensuring a secure and lasting seal.

RTJ Gaskets Style BX

The Style BX RTJ gasket is built for the most extreme conditions, capable of handling pressures up to 20,000 psi. This gasket is exclusively used with API 6BX flanges, providing unparalleled sealing integrity in critical applications. The BX design includes a pressure passage hole that ensures pressure equalization across the sealing faces, making it ideal for high-stakes operations.

Why Choose Our RTJ Gaskets?

Our RTJ gaskets are manufactured to meet stringent standards such as ASME B16.20 and API 6A, ensuring compatibility with a wide range of flanges including ASME B16.5, ASME B16.47 Series A, and API 6BX. The gaskets are designed with a focus on material compatibility, ensuring that they deform appropriately under pressure without damaging the flange surfaces.

In addition to our standard offerings, we provide specialized RTJ gaskets with protective coatings and inserts for enhanced performance in corrosive environments. Our gaskets are precisely engineered to prevent turbulent flow and minimize erosion, ensuring long-term reliability in your operations.

As a trusted supplier of Ring-Type Joint (RTJ) Gaskets in Malaysia, Mumtaz Energy offers high-quality gaskets that adhere to international standards, ensuring both safety and optimal performance for your projects. Contact us today to find the perfect gasket solution for your needs.

A Flange Insulation Gaskets is a specialized component used in pipeline systems, particularly in the oil, gas, and petrochemical industries. These gaskets are designed to provide an effective barrier against electrical currents that can cause galvanic corrosion between dissimilar metals. By electrically isolating the flanges, these gaskets help maintain the integrity of the pipeline, preventing potential damage from electrochemical reactions, especially in environments where stray electrical currents or cathodic protection systems are in place.

Function of Flange Insulation Gaskets

Flange Insulation Gaskets serve two primary functions: electrical isolation and corrosion prevention. In environments where pipelines are exposed to seawater, chemicals, or other corrosive substances, the risk of galvanic corrosion increases significantly when different metals are joined. The insulating properties of these gaskets prevent the flow of electric current between the flanges, thereby reducing the potential for corrosion. Additionally, they help to maintain the effectiveness of cathodic protection systems, ensuring that the pipeline remains protected over time.

Components of Flange Insulation Gaskets

A typical Flange Insulation Gasket Kit includes several essential components designed to work together to ensure complete electrical isolation:

- Insulating Gasket: This is the main component that sits between the flanges, providing a non-conductive barrier.

- Insulating Sleeves: These are placed over the bolts, preventing electrical contact between the bolts and the flange.

- Insulating Washers: These washers are used on each side of the flange to ensure complete isolation, preventing any conductive paths.

- Steel Washers: These are placed on top of the insulating washers to provide mechanical strength and distribute the load evenly across the flange.

Each component is made from high-quality materials with excellent dielectric properties, compressive strength, and chemical resistance, ensuring the durability and effectiveness of the gasket kit in various industrial applications.

How to Choose the Right Flange Insulation Gaskets

Selecting the correct Flange Insulation Gasket is crucial to ensuring the longevity and safety of your pipeline system. Consider the following factors when making your choice:

- Material Compatibility: The gasket material should be compatible with the pipeline materials and the substances being transported to avoid chemical reactions or degradation.

- Environmental Conditions: Assess the operating environment, including temperature, pressure, and exposure to chemicals or seawater, to choose a gasket that can withstand these conditions.

- Flange Type: Ensure that the gasket fits the specific type of flange (e.g., raised face, flat face, or ring-type joint) used in your system.

- Dielectric Strength: The gasket’s insulating properties should match the electrical resistance required to prevent current flow between the flanges.

By carefully considering these factors, you can select a Flange Insulation Gasket that provides reliable performance, enhances the longevity of your pipeline, and ensures the safety of your operations.

As a trusted supplier of Insulation Gaskets (Flange Insulation Kits) in Malaysia, Mumtaz Energy delivers high-quality products that meet international standards, ensuring safety and optimal performance for your projects. Contact us today to discover the perfect gasket solution for your needs.

Nonmetallic Flat Cut Gaskets

At Mumtaz Energy, we offer a comprehensive range of Nonmetallic Flat Gaskets, designed to meet the demanding needs of the oil and gas industry. Our gaskets are crafted from high-quality materials such as compressed non-asbestos fiber (CNAF), rubber, neoprene, and PTFE (Teflon), ensuring reliable performance across various applications. Each gasket is manufactured to conform to ANSI/ASME B16.21 standards, guaranteeing precision, durability, and safety.

NAF/CNAF/CAF Gaskets

Our NAF (Non-Asbestos Fiber), CNAF (Compressed Non-Asbestos Fiber), and CAF (Compressed Asbestos Fiber) gaskets provide exceptional sealing solutions for high-temperature and high-pressure environments. These gaskets are composed of synthetic and organic fibers bonded with elastomers, making them ideal for applications where asbestos is no longer an option. Key benefits include:

- Wide Temperature Range:

- Suitable for temperatures from -200°C to 400°C, offering stability in extreme conditions.

- Chemical Resistance:

- Excellent resistance to acids, alkalis, solvents, and oils, ensuring long-lasting performance.

- Environmental Safety:

- Asbestos-free, making them a safer and more environmentally friendly option.

Rubber/Neoprene Gaskets

Our Rubber and Neoprene gaskets are known for their versatility and resilience. Neoprene, also referred to as polychloroprene, is a synthetic rubber offering remarkable resistance to weather, chemicals, and petroleum derivatives. These gaskets are ideal for applications requiring flexibility and durability. Notable features include:

- Elasticity and Cushioning: Neoprene’s form-fitting nature allows it to conform to various sizes and shapes, providing an effective seal.

- Temperature and Weather Resistance: Withstands temperatures from -20°F to 180°F, making it suitable for diverse environmental conditions.

- Durability: Resistant to twisting, flexing, and damage from exposure to sunlight, ozone, and oxidation.

PTFE Gaskets

PTFE (Polytetrafluoroethylene), commonly known as Teflon, is a superior material for applications requiring chemical inertness and high-temperature resistance. Our PTFE gaskets are made from virgin-grade PTFE, ensuring purity and optimal performance in demanding conditions. Highlights include:

- Outstanding Chemical Resistance:

- Unaffected by most corrosive liquids, vapors, and gases, making PTFE the material of choice for aggressive chemical environments.

- Wide Operating Temperature Range:

- Performs reliably from -200°C to 260°C, suitable for both cryogenic and high-temperature applications.

- Non-Contaminating:

- Ideal for applications where hygiene and non-contamination are critical, such as in food and pharmaceutical industries.

Since 2017, Mumtaz Energy has taken pride in delivering nonmetallic flat cut gaskets across Malaysia, meticulously tailored to meet the highest standards and specific requirements of the oil and gas industry.

Gaskets Specification

| Specification | Options |

|---|---|

| Type | Spiral Wound Gasket Style S or Style R – sealing element (filler) only, Spiral Wound Gasket Style RS or Style RIR – inner ring and sealing element (filler) only, Spiral Wound Gasket Style CG – outer ring (centering ring) and sealing element (filler) only, Spiral Wound Gasket Style RSI or Style CGI – inner ring, sealing element and outer ring (centering ring) |

| Size | From 1/2″ (DN15) to 60″ (DN1500) |

| Rating | ASME/ANSI B16.50/BS1560, ASME B16.47 Series A (MSS SP-44), ASME B16.47 Series B (API-605) Flanges: 150#, 300#, 600#, 900#, 1500#, & 2500# JIS B 2220 & JIS B 2238-2240 Flanges: 10kgf/cm², 16kgf/cm², 30kgf/cm², 40kgf/cm², 63kgf/cm² To Suit DIN Flanges: PN10, PN16, PN25, PN40, PN100, PN160, PN250 |

| Standard | ASME B16.20, Metallic Gaskets for Pipe Flanges JIS B2404, Dimension of Gasket for Use with Pipe Flanges |

| Specification | Options |

|---|---|

| Type | RTJ Gaskets Style R Oval Shape RTJ Gaskets Style R Octagonal Shape RTJ Gaskets Style RX, in accordance to API 6A & ASME B16.20 to suit API 6B & ASME/ANSI B16.5 flanges RTJ Gaskets Style BX, in accordance to API 6A & to suit API 6BX flanges |

| Size | RTJ Gaskets Style R: R11 to R105 RTJ Gaskets Style RX: RX20 to RX215 RTJ Gaskets Style BX: BX150 to BX303 |

| Rating | ASME B16.50 Flanges: 150#, 300#, 600#, 900#, 1500#, & 2500# API 6B Flanges: 2000#, 3000#, & 5000# In accordance with ASME B16.20 & API Spec. 6A: 2000#, 2900#, 3000#, & 5000#, 10000#, 15000#, & 20000# |

| Standard | ASME B16.20, Metallic Gaskets for Pipe Flanges JIS B2404, Dimension of Gasket for Use with Pipe Flanges API 6A API 6B |

| Specification | Options |

|---|---|

| Type | F Type Gasket, RF Flange E Type Gasket, Full Face Flange D Type Gasket, RTJ Flange O Type Gasket |

| Size | 1/2″ (DN15) to 48″ (DN1200) |

| Rating | ASME/ANSI: 150#, 300#, 600#, 900#, 1500#, or 2500# |

| Standard | ASME B16.20, Metallic Gaskets for Pipe Flanges JIS B2404, Dimension of Gasket for Use with Pipe Flanges ASME B16.5 ASME B16.47 Series A ASME B16.47 Series B JIS B 2200 BS EN 1092-1 |

| Specification | Options |

|---|---|

| Type | CNAF/NAF – Compressed Non-Asbestos Fibre Elastomers – Neoprene, Nitrile, EPDM, FKM Viton, or SBR; Buna-S Graphite Sheet |

| Size | 1/2″ (DN15) to 32″ (DN600) |

| Rating | ASME/ANSI: 150#, 300#, or 600# |

| Standard | Suitable for flanges conforming to: ASME B16.5 ASME B16.47 Series A ASME B16.47 Series B JIS B 2200 BS EN 1092-1 |

Material Grade Standard

| Material | Standard/Grade/Symbol |

|---|---|

| Inner Ring or Outer Ring | Soft Iron (Armco) Stainless Steel 304/304L, 304S15/16/31, 304S11 Stainless Steel 309, 309S24 Stainless Steel 316/316L/316Ti, 316s11/13, 320S31 Stainless Steel 321, 316S31/33, 321S12/49/87 Stainless Steel 347, 347S31 UNS S31803 UNS S32750 UNS S32760 UNS S32205 Nickel 200, UNS NO2200, 3072-76 NA11 Monel 400, UNS NO4400, 3072-76 NA13 Inconel 600, UNS NO6600, 3072-76 NA14 Incoloy 800, UNS NO8800, 3072-76 NA15 Incoloy 825, UNS NO8825, 3072-76 NA16 Hastelloy B2, UNS N10665 Hasetlloy C276, UNS N10276 Titanium |

| Filler | Graphite or PTFE |

| Material | Standard/Grade/Symbol |

|---|---|

| Material | Soft Iron LCS CS360 LT, ASTM A516 Gr70 ASTM A182 F5, UNS K42544 Stainless Steel 304/304L, 304S15/16/31, 304S11 Stainless Steel 309, 309S24 Stainless Steel 316/316L/316Ti, 316s11/13, 320S31 Stainless Steel 321, 316S31/33, 321S12/49/87 Stainless Steel 347, 347S31 Nickel 200, UNS NO2200, 3072-76 NA11 Monel 400, UNS NO4400, 3072-76 NA13 Inconel 600, UNS NO6600, 3072-76 NA14 Incoloy 800, UNS NO8800, 3072-76 NA15 Incoloy 825, UNS NO8825, 3072-76 NA16 Hastelloy B2, UNS N10665 Hasetlloy C276, UNS N10276 Titanium 904L, 904L, N08904 ASTM A182 F51, UNS S31803 ASTM A182 F53, UNS S32750 ASTM A182 F55, UNS S32760 ASTM A182 F60, UNS S32205 17-4PH S254, UNS S31254 C276, UNS N10276 Alloy 28, N08028 |

| Material | Standard/Grade/Symbol |

|---|---|

| Insulating Gaskets | Metallic Core: SS316/SS316L, Duplex, or Inconel Gasket Insulating Material: GRE NEMA G10, GRE NEMA G11, Neoprene faced Phenolic, Klingersil C-4430, Klinger Topchem 2000, Klinger Topchem 2003 Seal Material: Spring-energized PTFE/Viton |

| Insulating Sleeve | Mylar GRE NEMA G10 GRE NEMA G11 Phenolic |

| Insulating Washer | NEMA GRE G10 NEMA GRE G11 Reinforced Phenolic |

| Steel Washer | SS316/SS316L or Mild Steel Zinc Plated |

| Material | Standard/Grade/Symbol |

|---|---|

| PTFE | Polytetrafluoroethylene Temperature range: -100°C to 240°C Non-reactive, water-resistant, minimal friction, often enhanced with fillers like carbon or graphite to minimizing creep under elevated pressures and temperatures. Teadit Sheet and Gaskets Teadit® PL 100, PTFE sheet with high compressibility Teadit TEALON TF 1590, Restructure PTFE with Silica Teadit TEALON TF 1580, Restructure PTFE with Barium Sulfate Teadit TEALON TF 157, Restructure PTFE with Glass Spheres Teadit 28 LS-LE, high pure ePTFE gasket with diffusion barrier Teadit 30 SH, 100 % ePTFE gasket sheet Teadit 24 SH, 100 % ePTFE gasket sheet |

| Fiber | BS7531 Grade Y Novus 30, Flexitallic SF2800, Klinger C4324, C4400, & C4500 plus Garlock Blue-Gard® 3000. 80 BAR and 400°C BS7531 Grade X Novus 10, 34, and 49, Flexitallic SF3300, 3500 & 5000, Klinger C4430, & Reinz AFM-34. 100 BAR and 425°C Teadit Compressed Fiber Sheet Selection Teadit NA 1002EU, high-end compressed non asbestos sheet material made of aramid fibers and bonded with NBR Teadit NA 1005, compressed non-asbestos sheet material produced from a blend of aramid and other synthetic fibers bonded with NBR Teadit NA 1006, compressed non-asbestos sheet material Teadit NA 1122, compressed non-asbestos sheet material with inorganic fibres, special fillers, bonded with NBR Teadit NA 1100, universal compressed non-asbestos sheet material manufactured from graphite and carbon fibre, bonded with NBR |

| Graphite | Teadit GR 1520, Graphite sheet with plain metal insert Teadit GE 1520, Graphite Sheet with tanged metal insert Teadit GP 1520, Pure expanded flexible Graphite sheet Teadit GR 1700, Graphite Sheet with multiple plain metal insert |

| Elastomer | Neoprene (CR ) Applications: Good oil and petroleum resistance. 940°C / 17 bar. Nitrile (NBR; Buna-n) Application: Good resistance to oil, solvents and fuels. 94°C / 17 bar. Ethylene propylene Diene Monomer (EPDM) Application: Good resistance to ozone, sunlight, acids, alkalis and ketones. Not suitable for fuels and oils. 120°C / 17 bar Fluoroelastomer (FKM) Viton® Application: Excellent resistance to heat and oil combinations and a wide range of concentrated acids and chemicals. 205°C / 17 bar. Styrene butadiene (SBR; Buna-S) Application: Good abrasion and impact resistance – general purpose sheet. Not suitable for oils, fuels and solvents. 94°C / 10 bar. |

Ordering Information

Ordering Information

2″ X 150# Spiral Wound Gasket, RF, SS316 Inner Ring, Graphite Filler, CS Centring, Thk 4.5 mm, ASME B16.20, ASME B16.5

Ordering Information

R-39 (4″ X 1500#), RTJ Gasket, ASME B16.20, Soft Iron, Octagonal

Ordering Information

6″ 150# Flange Insulation Kit

Retainer Gasket: NEMA Glass Reinforced Epoxy (GRE) G-10 with SS316 core,

Seal: SS316L Spring Energized PTFE,

Sleeves: NEMA Glass Reinforced Epoxy (GRE) G-10,

Insulating Washer: NEMA Glass Reinforced Epoxy (GRE) G-10,

Steel Washers: Mild Steel Zinc Plated

Type: To Suit TYPE F (RF) Flange

Ordering Information

Size : 6″, Rating : 150# FF, Flat Face Gasket, ARAMID FIBER WITH Nitrile Binder, 3mm THK, ASME B16.21